The Flow Conditioner is a tool employed to improve the fluid velocity profile across the flow segment. This apparatus is usually applied when you cannot fulfill pipe straight length necessities. Due to layout constraints, this frequently happens when it is not feasible to install a flow meter in a straight section of pipe appropriate to achieve suitable metering conditions.

This tool is likely to have the greatest fluid velocity profile, even if the straight pipe length is less than the minimum prescribed by the code.

Conversely, a flow conditioner introduces extra enduring pressure losses that shall be confirmed against procedure constraints.

Types Of Flow Conditioners

Flow conditioners offer the best practical ways to eradicate flow disturbances caused due to insufficient straight pipe runs and other poor pipe layouts. Flow conditioners are of the following types:

- Honeycomb vanes

- Perforated plates

- Tab-type flow conditioners

- Tube bundles

Below is the description of each type of flow conditioner along with its application based on:

- Process media

- Equipment problem

- Pipe configuration

- Cost requirement

General strategies for the best applications of flow technologies are as follow:

1. Honeycomb vane-type conditioners

These are often found in HVAC or compressed air handling system applications. These conditioners offer modest flow profile rectifications.

They come in various designs and materials. Each design should be suited cautiously to the particular use. Otherwise, they can be continuation rigorous or need recurrent replacement.

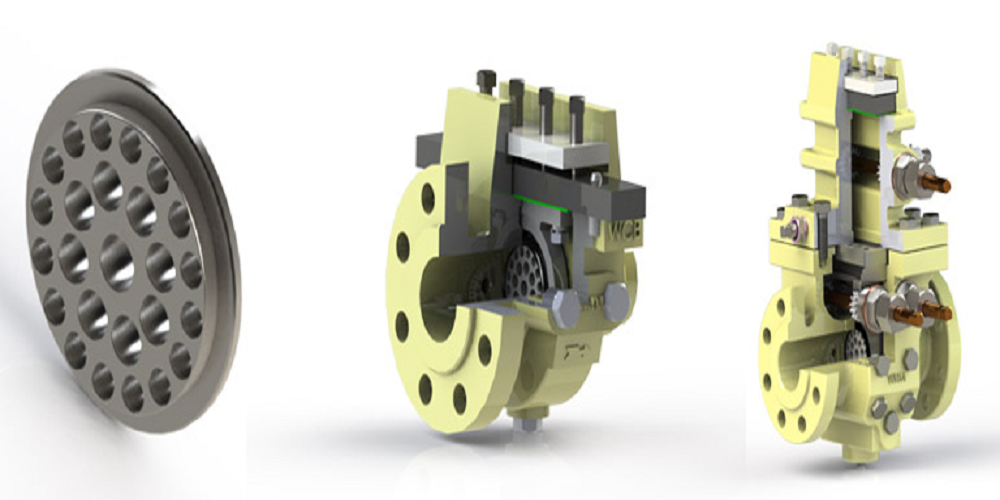

2. Perforated Plates

These are excellent options in:

- Natural gas pipelines

- Clean gas and liquid applications

They can be easily installed. They need no spool piece. However, they can be clog prone in filthy gas or solid-laden media. While effectual, they normally have an elevated head loss coefficient, so they might lead to more pressure drop than tube bundles or tab-type products.

3. Tab-Type Flow Conditioners

Due to the tapered tabs design, these conditioners are perfect for clean or filthy gases and liquids. They offer outstanding cross-mixing to eliminate swirl and rectify velocity profiles with nearly no pressure drop.

They are the only tools that can be retrofitted into elbows. Though, their design is inappropriate for most sanitary uses.

4. Tube Bundles & Vanes

These have been utilized for decades. Tube bundles decrease swirl in clean gases and liquids but do not rectify velocity profiles. These are inappropriate for custody relocation applications. Vanes also eliminate swirls; however, they cannot separate or eradicate flow irregularities.

Things To Consider While Selecting a Flow Conditioner

When making your choice or consulting with a vendor, make sure you know these key procedure variables:

- Solids content in the gas or liquid

- Viscosity range of the process media

- Bearable pressure loss vs. conditioning efficiency

- These elements are significant to ultimate assortment and appropriate installation.

Advantages

- They can eradicate approximately 80 – 90% of pipeline swirls.

- They can assist restore flow profile symmetry and removing distortions.

- You can use it to isolate the flow meter from upstream disturbances.

- Flow conditioner allows much shorter meter runs to be employed with much superior repeatability.

- They are applicable for all liquid or gas flows.

- The flow conditioner is simply helping out the meter, giving superior reproducibility and lesser ambiguity.

Shanghai Wan Hui Machinery Co., Ltd is providing an amazing collection of flow conditioners with quality and affordable price range. Click on https://www.whmcn.com/products/flow-conditioner/ to check the latest details and place your order.

Conclusion

Valves, pumps, compressors, and flow meters can all be influenced by flow disturbances due to poor piping layouts. For such problems, flow conditioners are an outstanding solution with a cautious and informed selection.