Hey, folks! Get ready for an authentic and down-to-earth product comparison and review of steel and aluminum forged factories. In this article, we’ll dive into these manufacturing facilities, breaking down their features, benefits, and performance. Our goal? To give you a real and unbiased perspective, helping you make a wise decision when it comes to choosing between steel and aluminum forged factories for your specific needs. So, let’s jump right in! Welcome to visit the CXIN FORGING to learn more!

Product Comparison:

Material Properties:

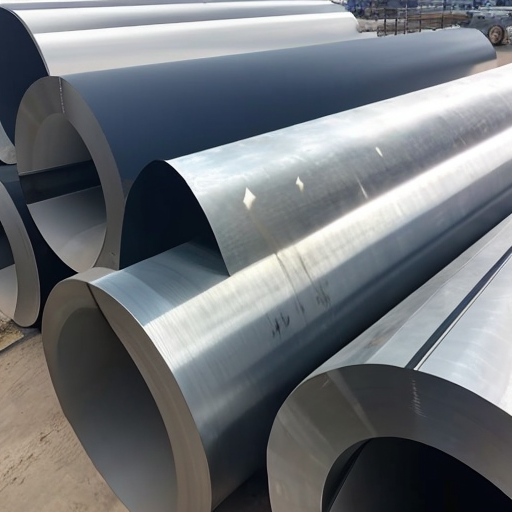

Steel forged factories are known for their incredible strength and durability. They produce components with high tensile strength, perfect for applications that demand tough and reliable performance. On the flip side, aluminum forged factories specialize in crafting lightweight components that boast good corrosion resistance. This makes them a go-to choice for industries where weight reduction is critical, like aerospace.

Customization Options:

Both steel and aluminum forged factories offer a wide range of customization options. Manufacturers can tailor the shape, size, and design of components to fit their exact requirements. However, it’s worth noting that steel forging allows for more intricate and complex designs, whereas aluminum forging is better suited for simpler geometries.

Application Range:

Steel forged factories find their place in diverse industries such as automotive, aerospace, oil and gas, and machinery. Their unparalleled strength and durability make them perfect for heavy-duty applications, withstanding wear, fatigue, and intense operating conditions. Aluminum forged factories, on the other hand, shine in industries where shedding weight is crucial, such as aerospace and automotive.

Objective Review:

Strength and Durability:

Steel forged components are the epitome of strength, making them a solid choice for demanding applications. They can handle heavy loads and harsh operating conditions, guaranteeing long-lasting performance. Although aluminum forged components aren’t as robust as steel, they still offer impressive durability and corrosion resistance, making them suitable for lighter-duty applications.

Precision and Quality:

Both steel and aluminum forged factories excel in achieving precision and delivering high-quality components. Through the forging process, they ensure excellent dimensional accuracy and surface finish, resulting in components that fit perfectly and perform optimally. So, you can trust that you’ll get top-notch precision and quality from either type of factory.

Cost-effectiveness:

Let’s talk about costs for a moment. Setting up a steel forged factory usually requires a higher initial investment due to specialized equipment and expertise. However, the long-term cost-effectiveness of steel forged components becomes evident through their extended service life and reduced maintenance needs. On the flip side, aluminum forging may have a lower initial cost, but keep in mind that it may require more frequent replacements in certain applications.

Industry Suitability:

The suitability of steel or aluminum forged components depends on your industry and specific application requirements. Steel components are commonly used in heavy-duty industries like construction, oil and gas, and machinery, where toughness is paramount. On the other hand, aluminum components find their sweet spot in industries where weight reduction plays a crucial role, such as aerospace and automotive, where every ounce matters.

Conclusion:

In this candid and genuine product comparison and review, we’ve explored the features, benefits, and performance of steel and aluminum forged factories. Steel forged components pack a punch with their unmatched strength and durability, while aluminum forged components offer lightweight options with good corrosion resistance. Both options provide customization and high-quality components. Ultimately, the choice between steel and aluminum forged factories hinges on your industry and specific application needs. By considering the features and benefits we’ve discussed, you’ll be equipped to make an informed decision that aligns perfectly with your requirements. Remember, finding the right fit is the key to achieving manufacturing success.