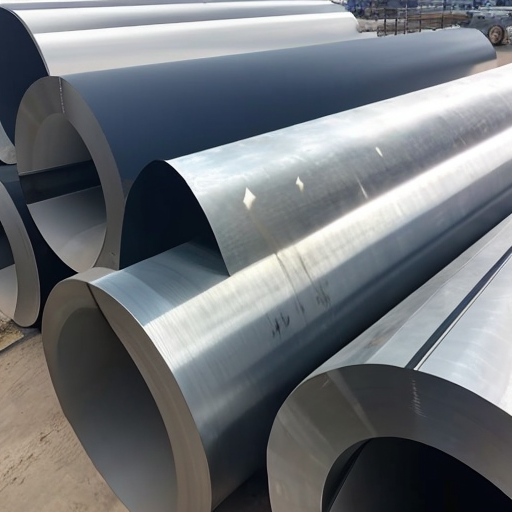

Commercial, industrial, and residential buildings all share a common need for reliable fire protection systems. Fire sprinkler systems are an important part of the arsenal used to prevent loss of life and property caused by fires. The Fire Sprinkler Pipe is the unsung hero at the centre of these setups.

A Lifeline During Fires

Sprinkler systems are the first line of defence against fires, as they quickly extinguish the flames and prevent them from spreading. A sprinkler system is a network of pipes strategically placed throughout a building, ready to spray water at the first sign of a fire. While these systems may not be able to put out fires like in the movies, they are very good at stopping the fire from spreading and giving people time to get out of the building safely.

The Role of Fire Sprinkler Pipes

The sprinkler pipes are the backbone of any fire protection system. These conduits are the blood vessels that deliver life-saving water to the inferno. They make sure that water gets into every part of the building, even the ones that are difficult to access, so that the fire can be put out more efficiently. Due to high temperatures, pressures, and the corrosive effects of water over time, fire sprinkler pipe is an important consideration.

Reducing Damage and Loss

Pipes equipped with fire sprinklers can significantly lessen the extent of destruction caused by fires. They contain the blaze by quickly releasing water, which stops it from spreading to other parts of the building. Because of this containment, not only is structural damage mitigated, but also loss of assets and personal property is kept to a minimum. Because they stop fires before they can spread out of control, fire sprinkler systems also significantly cut down on the water used in firefighting, which helps to keep water damage to a minimum.

Swift Response and 24/7 Protection

It makes no difference if a building is occupied or unoccupied when a fire breaks out. Continuous safety is ensured by fire sprinkler systems, which in turn rely on sturdy fire sprinkler pipes. Constantly on the lookout for any sign of fire, they are prepared to act at a moment’s notice. This preventative measure guarantees rapid firefighting, reducing the likelihood of loss of life and property.

Meeting Rigorous Standards

Standards for fire sprinkler pipes are extremely high for good reason. Pipes manufactured to these specifications will not burst under the extreme heat and pressure of a fire. Pipes that have been UL Listed or FM Approved have been proven to be reliable and effective in fire safety systems through extensive testing.

The Role of Installation and Maintenance

Fire sprinkler pipes must be properly installed and maintained on a regular basis in addition to having a high-quality design and construction. The reliability of the fire sprinkler system can be ensured through careful installation and regular maintenance and inspections. Poor installation or long-term neglect can reduce the effectiveness of even the highest quality pipes.

Conclusion

Fire sprinkler pipes may not always get the credit they deserve, but they play an undeniably important role in preventing fires. They’re the unsung heroes who get water to the fires quickly and effectively, turning the tide and saving lives and property. Without fire sprinkler pipes, buildings and their occupants would be unprotected from the dangers of fires. Therefore, it is crucial to raise awareness of fire safety and ensure that these seemingly insignificant parts are not overlooked.