In the world of manufacturing, quality is paramount. When it comes to processes like injection molding, where precision and consistency are essential, ensuring quality is a top priority. One powerful tool that manufacturers turn to for this purpose is ISO 9001 certification. This internationally recognized standard helps injection molding companies like Kemal Precision Manufacturing (www.kemalmfg.com) achieve and maintain the highest levels of quality in their operations.

Understanding ISO 9001 Certification

ISO 9001 is a quality management system standard developed by the International Organization for Standardization (ISO). It sets out the criteria for a quality management system and is based on a number of quality management principles, including a strong customer focus, involvement of top management, a process approach, and continual improvement.

ISO 9001 certification is not a mandatory requirement, but many companies choose to pursue it voluntarily because of the significant benefits it offers. This certification serves as a clear signal to customers, partners, and stakeholders that a company is committed to maintaining high-quality standards in all aspects of its operations.

Quality in Injection Molding: Why It Matters

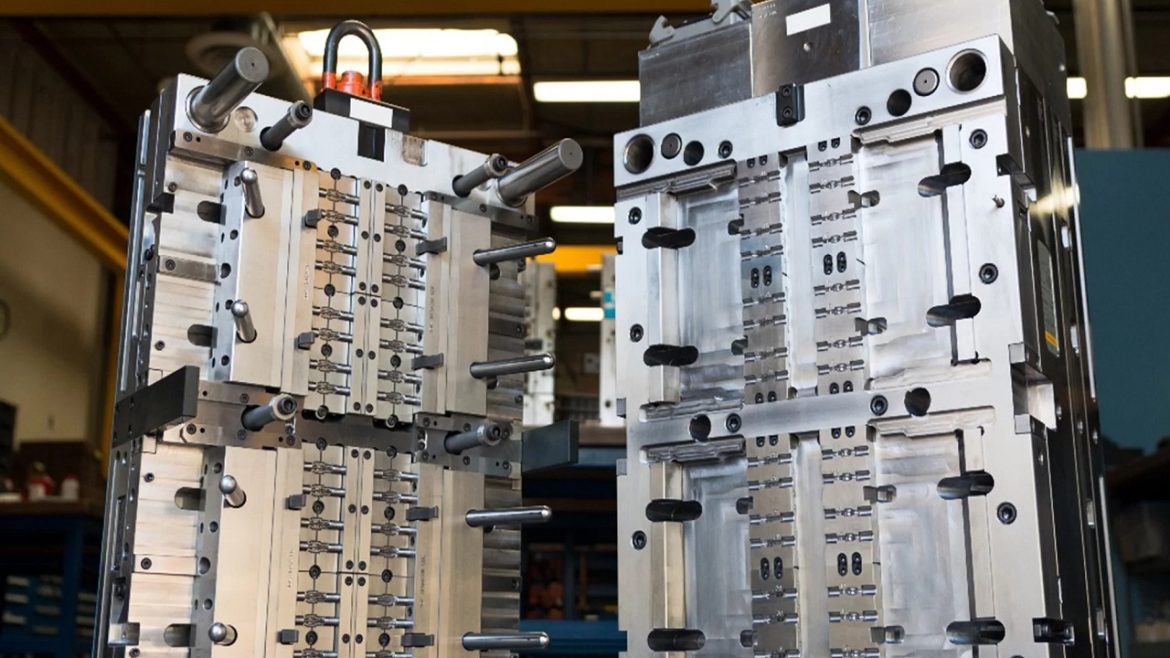

Injection molding is a manufacturing process used to produce a wide range of plastic parts and products. From automotive components to medical devices and consumer goods, injection molding plays a pivotal role in various industries. The quality of the final product is directly influenced by the quality of the injection molding process.

Here are a few reasons why quality is crucial in injection molding:

- Product Performance: High-quality injection molding ensures that the final products meet or exceed performance expectations. This is particularly critical for safety-critical applications like medical devices.

- Cost Efficiency: Quality control helps reduce waste and rework, leading to cost savings in the long run.

- Customer Satisfaction: Consistently delivering quality products leads to satisfied customers who are more likely to become repeat clients.

How ISO 9001 Certification Enhances Quality

ISO 9001 certification is a systematic and process-driven approach to quality management. Here’s how it helps ensure quality in injection molding:

Standardized Processes

ISO 9001 requires organizations to establish and document clear processes. In the case of injection molding, this means having well-defined procedures for material handling, machine setup, molding, and quality checks.

Risk Management

ISO 9001 encourages companies to identify and mitigate risks. In injection molding, this can involve assessing factors that could affect product quality, such as temperature and pressure variations.

Continuous Improvement

The standard promotes a culture of continuous improvement. Companies like Kemal Precision Manufacturing regularly review their processes and make necessary adjustments to enhance efficiency and quality.

Customer Focus

ISO 9001 emphasizes understanding and meeting customer requirements. Injection molding companies with this certification prioritize customer satisfaction and are more likely to deliver products that align with customer expectations.

Choosing a Certified Injection Molding Partner

For businesses seeking an injection molding partner, looking for ISO 9001 certification can be a valuable criterion. This certification provides assurance that the manufacturer is committed to maintaining high-quality standards and has a structured approach to quality management.

Conclusion

In conclusion, ISO 9001 certification is a powerful tool for ensuring quality in injection molding processes. Companies like Kemal Precision Manufacturing understand the importance of this certification and leverage it to consistently deliver high-quality products to their customers. Whether you’re in the automotive, medical, or consumer goods industry, partnering with an ISO 9001-certified injection molding company can lead to improved product quality, customer satisfaction, and overall business success.