Plastic Injection Molding

The injection molding process is one of the main production processes in the processing of plastics. Injection molding has some features that provide a beneficial application of this method, especially in the manufacture of complex molded parts as mass-produced. These features are:

- Direct route from the raw material to the finished part

- No or only minor post-processing of the molded part is necessary

- Fully automated and process

- High reproducibility of production

The range of molded parts that can be produced by injection molding extends from the smallest of gear wheels or bearings to large waste containers. The weights of the molded parts are in the order of 0.001 g to 100 kg.

Machine and process flow

The task of an injection molding machine according to DIN 24450 comprises the discontinuous production of moldings of preferably macromolecular molding compositions, wherein the primary molding is done under pressure.

process flow

For this purpose, it is necessary to convert the material supplied by the raw materials manufacturer usually in granular or powder form (elastomers usually in the form of strips) so that it is converted into a flowable state. First, the material is plasticized by rotation of the screw (Figure 1). After closing the mold (step 1), which has a cavity corresponding to the molding, the plasticized material is injected by axial feed of the screw into the tool (step 2).

Figure 1: Process flow in injection molding

For thermoplastic materials, the melt is subsequently cooled in the mold (step 3). In the case of crosslinking materials (thermosets, elastomers), the tool is heated, thus initiating the crosslinking process. The last step involves opening the tool and ejecting the molding (step 5).

The outlined process steps, which sometimes overlap in time, are part of every injection molding cycle. In the production of an injection molded part, the individual production steps, which are shown again in greater detail in Figure 2, are coordinated by the control device of the machine.

Figure 2: Injection Molding

The aim in the economic production of a molded part is to reduce the cycle time required for this process in order to achieve a high output.

In addition to the above-mentioned method steps can perform other functions, such as the movement of the unit, actuation of core pulls u. a. m., However, these do not change the basic procedure.

machine design

Irrespective of the material to be processed, an injection molding machine is made up of the following assemblies (Figure 3): The machine bed is used to hold the plasticizing unit and clamping unit. The latter serves to realize the opening and closing movement of the tool during the production cycle. The course of the injection molding cycle is coordinated via a control or control unit, which is usually housed in a separate cabinet from the machine.

Figure 3: Construction of an injection molding machine

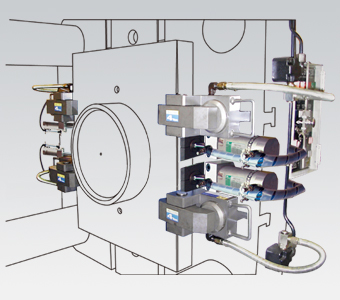

The drive of the screw located in the plasticizing unit as well as the closing unit is carried out hydraulically or via direct electrical drives. The pumps required to provide the required hydraulic oil volume flow are housed in the machine bed and are driven electrically. The hydraulic valves required for the control of the individual movements are as far as possible in the immediate vicinity of the consumers to whom they are assigned. To operate additional functions such. As ejector, nozzle or for moving core trains, additional purely electromechanical or pneumatic drives are used.

In the following explanations only machines are to be considered whose main movement mechanisms (plasticizing, injecting, opening / closing tools) are hydraulically realized, since this type of machine is predominantly found in practical use, but all-electric machines are becoming increasingly important.

To cool the injected molten plastic, the molding material must be cooled under solidification temperature in thermoplastics before the molding can be removed from the mold. (In the case of crosslinking molding compounds, the tool is heated in order to trigger the crosslinking process). To this end, tool tempering devices (also referred to as tempering unit) are necessary. These can be an integral part of the machine or be placed as an external unit to the machine.