CNC (an abbreviation for ‘computer numerical control’) milling is a process, which utilizes computerized navigations and helps to carry out design work. To understand the concept of CNC milling deeply, one needs to know about what it means to mill. Milling deals with the act of drilling or piercing a surface to get a particular design style.

Moreover, CNC milling is almost similar to other processes. The only difference is that this process is carried out manually. In CNC milling, you need to program the specific design on the miller machine, which makes drilling operations on surfaces (such as wood, glass, metal, and plastic) easy and fast.

What is a CNC milling machine?

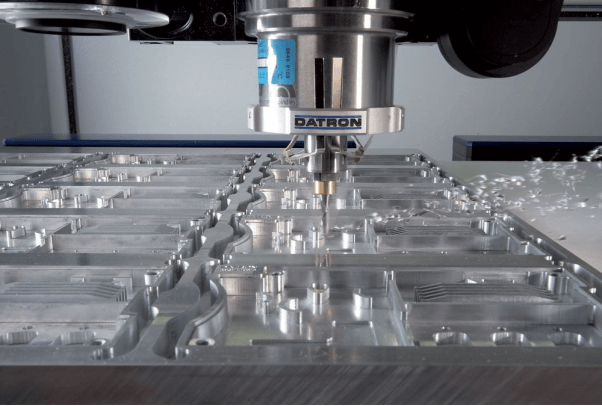

A CNC milling machine refers to robotic drilling equipment that can be used to mill and create custom designs on surfaces like hard plastic, metals, and wood. CNC milling machine is mostly used to drill or cut hard and heavy metals such as alloys and titanium. These machines are mostly employed in industries because they have an accurate precision on metals, plastic, and wood materials. CNC milling machines are of various types and perform multitudinous tasks. Most times, CNC milling machines are classified based on the number of axes on which they can operate.

Types of CNC milling machines

CNC vertical milling machine

This milling machine has cutters and drillers programmed vertically on a rotating axis. CNC vertical milling machine is best used for security, industrial, recreation, and transportation works.

CNC turret milling machine

This type of drilling machine is one of the most used milling equipment employed by industries with mass production. Besides, the spindle of turret millers can be turned and programmed to any position.

CNC bed milling machine

CNC bed millers are quite similar to turret milling machines. The milling machine makes its movement opposite the axle. The axle is the only part of the machine that makes a parallel movement to the cutting point or axis.

CNC horizontal milling machine

CNC horizontal milling machine is not quite different from vertical millers. The only difference is that a horizontal miller shaves off particles from the surface rather than drilling it. This type of machine makes use of a universal table for its production as well.

Uses of CNC millers

CNC millers are used for various industrial operations and on different surfaces. The main uses of CNC millers are listed below.

- CNC millers are used for removing metals: CNC milling machines are effective in removing metal materials from iron components. CNC millers are used by automotive companies to make gears and shafts.

- CNC millers can be used to manipulate metals: CNC milling machines can be used to make products like steel plates, cups and mainly, to reshape raw metal material to a refined state or design.

Other areas where CNC machining can be used are wood making, embroidery, foam cutting, glass cutting, and turret punching.