Plastic prototypes represent final plastic objects created by manufacturers through multiple methods such as plastic injection molding. They give both the manufacturer and client a feel of the outcome and a blueprint to follow through the machining process. The injection molding process is a quick and affordable way to produce plastic prototypes. It allows the production of high-quality products with great standards and is ideal for the market. In this article, we outline the plastic prototype formation process using injection molding.

How to Use Injection Molding to Create Plastic Prototypes

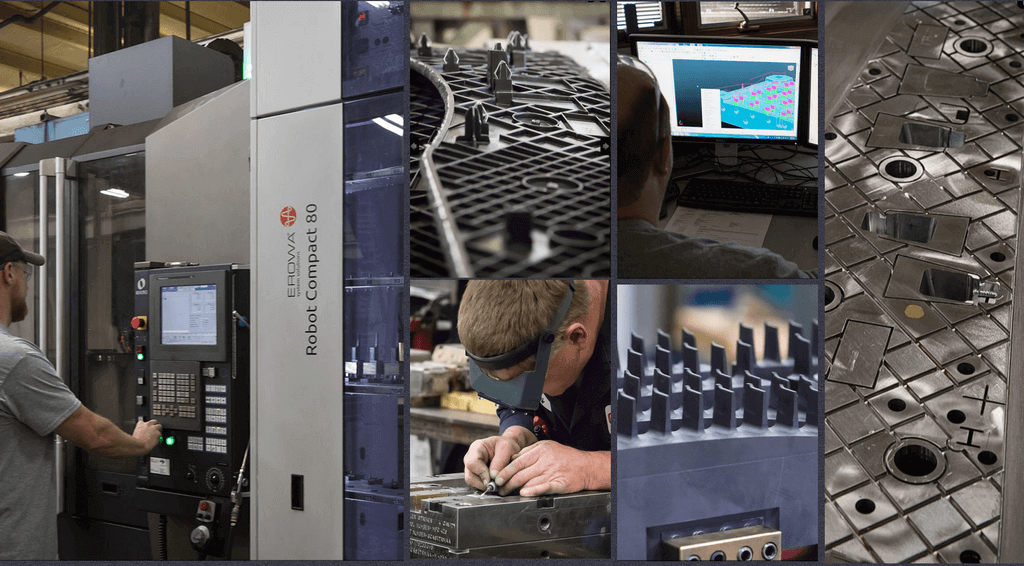

Injection molding is a manufacturing technique that involves the injection of molten into a mold. Some popular plastic materials used in this process are Nylon, PP, ABS, Polyethylene, and HIPS. There are four significant steps for creating plastic prototypes. They include;

1. Developing the product design

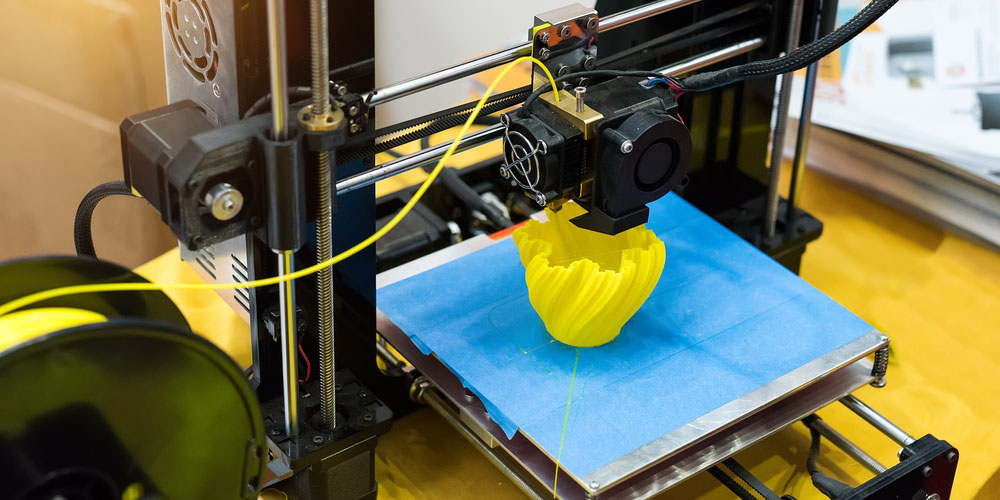

In manufacturing, the design concept is always the first step to achieving a prototype. You must carefully do the design to avoid errors and ensure it is functional and feasible. If the design is wrong, there’s a high chance the final product will have issues; hence you are forced to design again from scratch. 3D prototyping is used for concept realization.

Files are made using CAD software which comes in different formats like STL and STP files. Involve a plastic design expert to assist in the process. Communicate your concept clearly to ease the process. The design will only pass this state if it meets the set guidelines and proves doable.

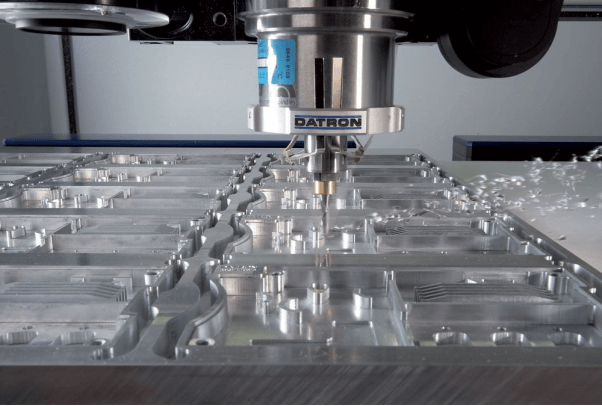

2. Development of the plastic products

Getting to this stage means the design has passed the test. The plastic prototype machining begins by gathering the necessary plastics to form the product. The manufacturer ensures the materials are tapered, making them easy to eject and inject into a mold. These services take place in a steel tool. The plastic parts should have the ideal thickness and no undercuts to prevent cracks or stick on the steel tool.

The wall thickness of the plastic parts influences the size of the gate where they should flow into. Most manufacturers can adjust the size of the walls to suit the gate and avoid overflowing. Make sure no air is trapped in the process by assessing the materials beforehand.

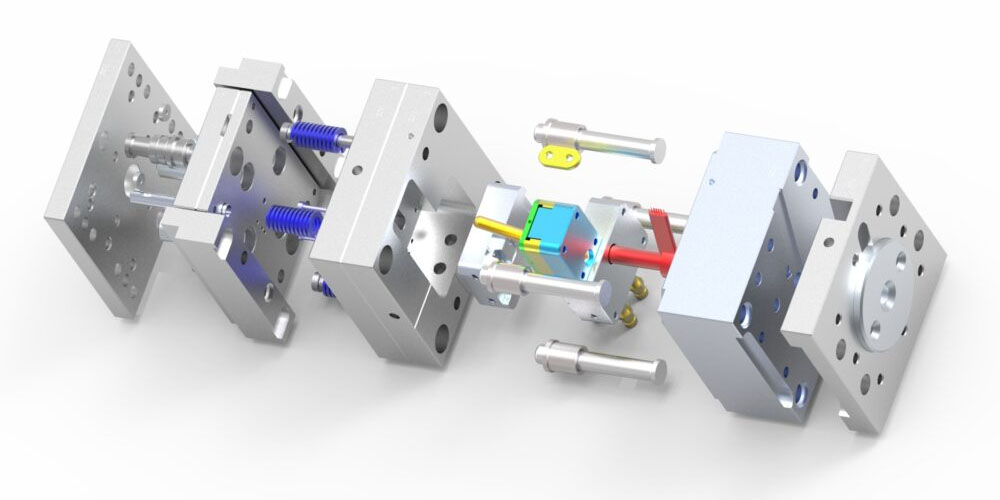

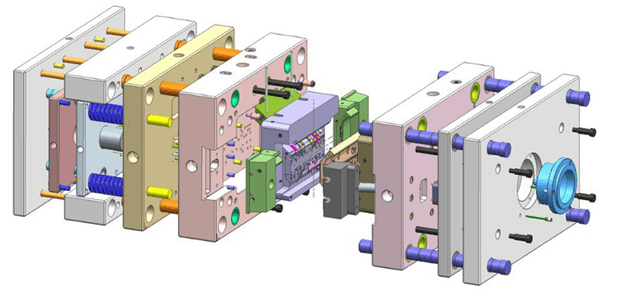

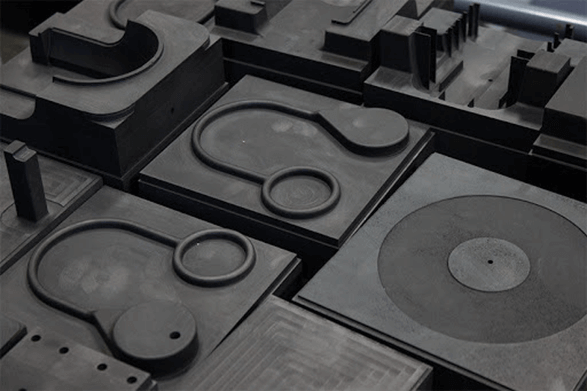

3. Creation of the mold

It is the most important process in plastic prototyping. Here, you can make both simple and complex molds. 3D printing is ideal for simple molds, while resins are used for complex molds. Plastic prototype injection molding uses plates to push the mold housing melted plastic and later cooled using water. The steel used in a simple design is soft, and you can manipulate it with ease. Other than the two mold haves, you need more material pieces for more intricate designs.

4. Using the injection molding machine

After completing the mold, it is placed in the injection molding machine and injected with plastic material. The plastic is put in a heated barrel to melt before being injected into the mold. The melted plastic is injected into the mold held by a clamp. Water lines then cool and solidify it. Once the cooling process is over, the mold is released from the clamp, making it open and forming the plastic design.

Conclusion

Producing plastic prototypes is to develop a perfect high-quality model before producing the actual product in bulk. It minimizes errors, gives you time to correct them, if any, and allows you to perform design alterations. Plastic prototype injection molding machining is a simple process that requires fewer materials and is quite affordable for customers.