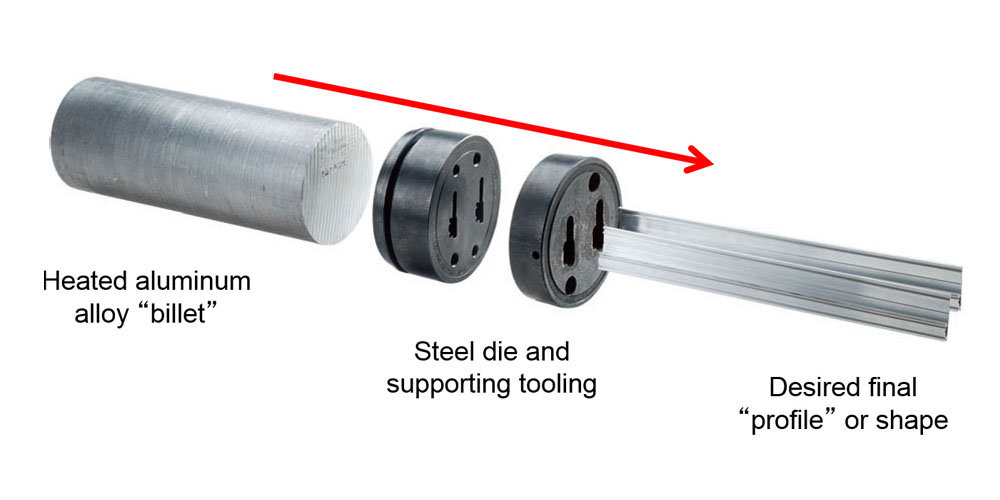

Steel extrusion is one of the steps of the steel fabrication process. In the extrusion process, an expert pushes molten metal through a pre-shaped die to enter a cross section through a cylindrical billet. Once the steel extrusions manufacturers cast and extrude the parts, they use a hydraulic or mechanical machine to push them out. Steel extrusion is most effective when extruding metals like steel, magnesium, aluminum, and stainless steel.

How Does Steel Extrusion Work?

Whenever you are working with molten metal, you need to strive to control the temperatures. Machines used in steel extrusion have provisions for lubrication. Lubrication ensures that the extrusion parts’ temperatures are regulated. Just like other metalworking procedures, the steel extrusion process can use cold or hot production methods. The hot extrusion technique uses heating elements like a furnace; therefore, it involves extremely high temperatures that may be problematic if not controlled. Lubricants will cool down the parts of the process.

Amazing Benefits of Using Steel Extrusions

Some of the main advantages of using steel extrusions are:

- You can produce a variety of different metals quickly and efficiently.

- You will minimize material wastage.

- Steel extrusions will increase your production rate.

- You will reduce your production expenses.

- The high pressure used in the steel extrusion process will allow you to manufacture products with an excellent finish.

- The extrusion process will enable you to manufacture metals with a high corrosion-resistance property.

Important Things To Remember During Steel Extrusion

When extruding steel, you need to remember a few things to get the process right. One of the elements to keep in mind is the metal type. Some metals are too brittle and cannot withstand the extrusion process.

Moreover, you will want to consider the wall thickness. Steel extrusion takes place under very high pressure. Therefore, if you have thinner walls, they will not survive the pressure exerted on them. For example, the maximum wall thickness for steel extrusion is three millimeters.

Steel Extrusion Shapes and Sizes

Traditional metal forging techniques may cause unexpected delays when casting new shapes. On the contrary, steel extrusion allows you to produce a myriad of different shapes effortlessly. You only need to prepare the wall and extrusion machinery and set everything in motion. After that, the process will take place faster. Additionally, the process allows you to set the scale and produce extruded parts with the correct size.

Custom Steel Extrusion

One of the best things about the steel extrusion process is that you can quickly manufacture metal parts for different industries, whether it is energy, healthcare, or the automotive sector. You can customize the metal parts to fit the needs of a wide range of sectors.

What To Expect From Steel Extrusion Suppliers

You need to find reputable steel extrusion manufacturers to ensure the process goes smoothly. The best team should have vast experience in the steel extrusion process and highly trained specialists to guarantee you exceptional services.

Conclusion

Many industries have adapted the steel extrusion process because it minimizes material waste, increases the rate of production, and decreases manufacturing costs. The information in this article will give you more insight into the process of extruding steel.