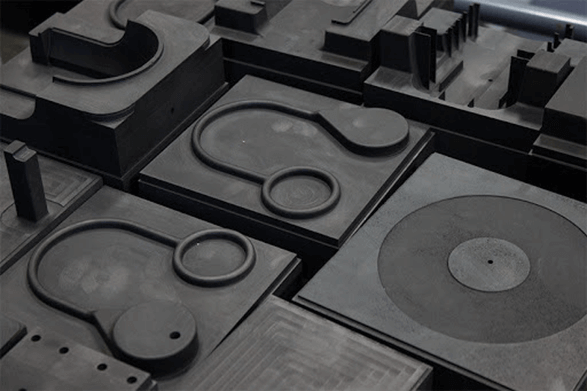

process of nylon injection moldingNylon (PA) is a widely popular material that is used in making rubber, clothing, various threads, vehicle parts, mechanical equipment, and so on. This material is easy to clean, strong, elastic, resistant to abrasion, and so on. Its features make it the perfect replacement for low strength materials.

Because it can be extruded, Nylon (PA) is the ideal material for both 3D printing and injection molding. Nylon’s high melting point makes it the single most suitable material for parts that need to be in an environment in which there are constant high temperatures.

However, nylon injection molding is not a simple process, and one that can lead to frustrations and headaches. We must get into it armed with knowledge about its properties, weaknesses, peculiarities, and how to make the most of it.

Here we will address some of the most common issues that need to be taken into consideration during the process of nylon injection molding.

Shrinkage

Nylon is the type of material that is liable to shrinkage. As a result of shrinkage, there can be dimensional variations, poor color, reduced strength, or even warping. The best way to avoid that is to control the process through the mold temperatures.

Adding temperature is often used to increase the cycle time, which leads to improved part properties. At the same time, it is essential to know that shrinkage takes time. In most cases, the shrinkage is completed within one hour, but sometimes it can be as long as 24 hours to be finished in full.

Moisture

Nylon is one of the most hygroscopic materials used in injection plastic molding. That means it can easily absorb moisture, which can be quite an issue. It is of great significance to make sure that the material is fully dried before it is sent to the loader. Take note of the appearance the purge needs to have so that you know the material is ready to be injected. Additionally, make sure that the nylon is not over dried either. Over dried materials have a yellowish appearance, which can also lead to poor quality products.

Gassing

Gassing is the single biggest issue with nylon injection molding that can lead to chalky/poor appearance and improper filling in detail areas.

One of the primary reasons for gassing is improper initial temperature. If the temperature is too high, it will lead to gassing. At the same time, if the initial temperature is too low that can lead to burns and shear. To avoid gas, it is for the best to follow the recommendation given by the material supplier.

Poor ventilation can also lead to excessive gasification. Monitor gassed vents closely as they determine when the mold needs to be cleaned. Typically, a nylon running mold is cleaned at least once per shift.

Final Thoughts

Nylon injection molding can be as challenging as it can be rewarding. Careful consideration of all production aspects, the condition of the material, the condition of the mold, and regular monitoring are key to successful nylon molding. That’s what makes the difference between top quality output and a mediocre one.