Custom plastic molding refers to the production of unique plastic designs using the injection moulding process. Through injection moulding, manufacturers can achieve custom and intricate designs that would otherwise be difficult to achieve. Injection moulding is also a cheaper method of producing parts in massive amounts. The technique has been in existence for more than a century but became popular in the late 1900s after the introduction of plastic injection moulding. The quality of the products of injection moulding is also an advantage. In this post, we look at the factors that affect the quality of the injection mould products.

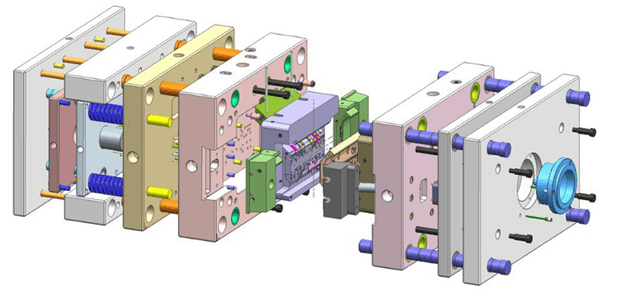

Tool Design

Tool design is an essential piece of the injection moulding process because how an item is injection moulded will have suggestions for its quality, value, and toughness. For instance, designing an instrument where the cooling procedure can be brilliantly overseen can diminishing in the last item and continue fabricating resistances tight. Guaranteeing that an item is designed-for-manufacture and getting the ideal injection shape instrument can have a significant effect on item quality, speed of production, unit cost, and profitability.

Material

The material used in the injection moulding process significantly affects the quality of the results. For instance, it affects the durability, strength, and value of the end product. The material used in making the mould also affects the quality of production. For instance, mould-made from steel is the best quality and makes the best products.

Processing of the mould

Sharp instruments do great work. The plan of the moulding process is especially significant, and a sensible procedure game plan can accelerate the creation cycle, minimize the preparing time, and adequately reduce the number of expenses. Also, more significantly, precise and sensible mould processing can guarantee steadiness and a life span of shape during the creation process.

Some machining blunders usually prompt form welding, regardless of how great the welding is, it is a misfortune to custom plastic trim. What’s more, poor preparation may influence form development, lessen shape life, and cause the form to break during the creation process or even broken.

Structure of the mould

The best mould structure is exceedingly considerate of the item material properties, shrinkage rate, forming temperature, versatile tractable twisting coefficient. Additionally, the cooling conduit or waterway, speed of opening and shutting mould is also affected by the mould structure. Sensible mould structure can successfully expand the life of shape and guarantee the smooth creation of a form, improve proficiency and lessen costs.

Assembly of the final product

The injection moulding process is used only for the manufacture of parts of a larger product. The parts then have to be put together in an assembling process. The assembly of the product dramatically influences the quality of the final product. You, therefore, have to make sure that every component goes where it is supposed to be. Defaults in the assembly process result in defaults in the quality of the product.

Take Away

The plastic injection moulding industry is one of the largest in the globe. It comprises manufacturing of items using plastic moulding and the manufacturers of the injection moulding machines.